Unmistakeable, unparalleled style. The Lamborghini Trend family combined the brand's innate style with state of the art technology, superlative efficiency and extraordinary reliability. The superior productivity of the new, fuel-sipping 3 and 4 cylinder FARMotion engines is complemented to perfection by the new layout of the driver zone and many other new features. Thanks to the 4-wheel brake system - available as- standard equipment - these machines make no compromises where safety is concerned.

Additional Info

- Subtitle 70 - 80

- claim The simple elegance of hard-working productivity.

-

design intro

Why just work when can work with style?

-

design

The sinuous forms of the Lamborghini family style lend Spire F Trend tractors a sense of unique elegance that makes a clear impression when you're working in the vineyard or fruit orchard.

-

engine intro

The FARMotion 35 engine is a powerplant with class-beating characteristics designed and built specifically for agricultural applications.

-

engine

FARMotion 35 engines are turbo-intercooled and feature electronically controlled common rail fuel injection with injection pressures up to 2000 Bar. Compliance with Stage V emissions regulations is achieved with a lightweight external cooled EGR system combined with a simple, maintenance-free DOC catalytic converter and passive DPF. The Exhaust-After-Treatment does not require the use of additional fluids (AdBlue). Furthermore, thanks to its perfect integration with tractor layout, the system does not impact the dimensions of the tractor, ensuring a low-profile shape of the bonnet.

-

transmission intro

Efficient, simple to use and totally configurable: the defining traits of the transmissions equipping Spire F Trend tractors.

-

transmission

Lamborghini Spire F Trend tractors are equipped with essentially all-mechanical, fully synchronised transmissions, making them extremely simple to use, efficient and reliable. The extensive choice of configurations offered includes transmissions based on 4 or 5 speed gearboxes with 2 or 3 ranges, which may also be combined with creeper and underdrive gears, to offer from 8+8 to 30+15 speeds in total. Whatever the configuration chosen, all transmissions allow the tractor to comfortably reach a top speed of 40 km/h, for more practical usage for transport tasks and driving on public roads.

-

hydraulic system intro

Simple, potent, efficient and configurable to suit your precise needs.

-

hydraulic system

An 18 l/min pump delivers oil exclusively to the hydraulic steering system, for impeccably smooth steering even at the lowest engine speeds. The lift and (4 or 6 way) distributors are fed by a separate, dedicated pump with a delivery rate of 42 l/min (or, as an option, 50 l/min). The 3-point rear linkage is available as either a standard version or a compact version, which minimises the space needed to manoeuvre at the end of the row.

-

cab intro

Simple, rational and comfortable.

-

cab

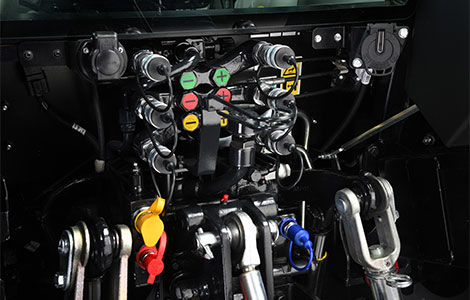

With a smaller centre tunnel, the driver's area offers even more comfort than ever. For unparalleled simplicity, the driver zone features the tried and tested colour-coded control scheme, with controls organised in a functional, ergonomic layout around the driver, making them immediately and intuitively identifiable with no guesswork. Solutions that take the stress out of your daily work.

- Sheet Version number 70|80

- Maximum power (hp/kW) 48,9/66 | 55,8/76

- Homologated power (2000/25/EC) at rated engine speed (hp/kW) 48/65 | 55,2/75

- Maximum torque (Nm) 297|341

- Cylinders / displacement (n°/cc) 3/2887

- Lifting capacity (kg) 2700 (compact) / 3050 (standard)

- Minimum width (mm) 1450-1642

- Weight with ROPS (kg) 2189

- TECHNOLOGIES EGR, DOC, ALL-WHEEL BRAKES, PARK-BRAKE

-

Categorization

- Categorization Power Range Min 70

- Categorization Power Range Max 80

- Categorization Track Width Min 1422

- Categorization Track Width Max 1642

- Categorization Cylinders n. 3, 4

- Categorization Trasmission MECHANICAL

- Stock Availability N

By nature, a Lamborghini tractor has stylish looks that could never be mistaken for anything other than a Lamborghini. But above and beyond its unrivalled elegance, the Spire Trend also boasts state of the art technology conceived for efficiency and reliability, with new 3 cylinder FARMotion 35 engines, a highly efficient transmission, an all-new driver station layout and many other innovative new features.

Additional Info

- Subtitle 70-80-90-100

- claim Unmistakeable style, outstanding productivity.

-

design intro

Eclectic, eye-catching looks.

-

design

With the sinuous, aggressive forms of the Lamborghini design language, Spire Trend tractors flaunt a stylish elegance that stands apart from the crowd in any situation. The low profile cowl, the design of the air intakes and the intelligent configuration of the lights hint at the painstaking attention to detail that went into the project for the Spire Trend, to accentuate the premium quality typical of the Lamborghini Trattori brand.

-

engine intro

A modern, compact and efficient engine.

-

engine

The new Spire Trend is powered by the latest generation 3 cylinder FARMotion 35 engine, a powerplant conceived specifically for farming with significantly more compact dimensions and lower noise emissions and fuel consumption than before. The new configuration of the heads and combustion chambers, combined with 2,000 bar Common Rail fuel injection, improve combustion efficiency, maximising engine performance while reducing fuel consumption. Thanks to electronically controlled external EGR exhaust gas recirculation combine with a DOC+DPF (70-80 models) or DOC+DPF+SCR (90-100 models), FARMotion 35 engines comply with Stage V emissions control regulations.

-

transmission intro

The right ratio for every job.

-

transmission

Spire Trend tractors are offered with a choice of different transmission configurations to cater for any possible need. The base variant consists of a modern 5 speed gearbox with 3 ranges. As an option, a splitter (controlled from a lever situated conveniently under the steering wheel) may be added to double the number of forward speeds offered, increasing the number of ratios available from 15+15 to 30+15. Tractors equipped with Powershuttle can be even fitted with a Hi-Lo 2-Powershift steps, while as standard offers always Stop&Go, ComfortClutch and SenseClutch functions. For maximum traction and draft in all conditions, electrohydraulically engaged all-wheel drive and differential locks are standard.

-

hydraulic system intro

Comprehensively equipped with high performance features.

-

hydraulic system

For maximum productivity with any implement, Spire Trend tractors are equipped as standard with a 56 l/min hydraulic pump and with 4-way (or optional 6-way) mechanically controlled auxiliary distributors. For uncompromised safety and impeccably smooth steering action even at the lowest engine speeds, the steering circuit is fed by a dedicated, separate 20 l/min pump. The mechanically controlled rear lift has a maximum capacity of 2,500 Kg as standard, which may be increased to 3,500 Kg as an option. In addition is now available the EasyLift control that allows to raise and lower the implements using a single button on the consolle. The PTO comes as standard with 540 rpm and 540 ECO speed modes, while a 1,000 rpm mode or ground speed mode may also be added as an option. A practical lever lets the driver engage the dedicated PTO clutch precisely and progressively.

-

cab intro

Class beating comfort and ergonomics.

-

cab

The stylish and supremely comfortable new cab of Lamborghini Spire Trend tractors offers extraordinary visibility and features the most user-friendly control layout in its class. The entire driver station has been optimised to offer the operator a rational and ergonomic working environment. The driver seat is equipped with mechanically sprung suspension (or, as an option, air-sprung suspension) adjustable to perfection to suit the weight of the operator. All the controls are right at the driver's fingertips, while the new analogue/digital display moves together with the adjustable rake steering column to ensure that all the main operating parameters of the machine are clearly visible at all times.

- Sheet Version number 70| 80 | 90 |100

- Maximum power (hp/kW) 48,9/66|55,8/76|67/91|75/102

- Homologated power (2000/25/EC) at rated engine speed (hp/kW) 48/65|55,2/75|63,5/86|71,1/97

- Maximum torque (Nm) 297|341|372|417

- Cylinders / displacement (n°/cc) 3/2887

- Lifting capacity (kg) 2500/3500

- Minimum width (mm) 1882

- Weight with cab (kg) 3250|3350

- TECHNOLOGIES EGR, DOC, Stop & Go, Over Speed, ALL-WHEEL BRAKES, PARK-BRAKE

- Weight with cab (kg) 3250|3350

-

Categorization

- Categorization Power Range Min 70

- Categorization Power Range Max 100

- Categorization Track Width Min 1795

- Categorization Track Width Max 1882

- Categorization Cylinders n. 3

- Categorization Trasmission MECHANICAL

- Stock Availability N

Electronics make agricultural machinery smarter, more powerful, more precise and more efficient.

Written by Web SupportThe concept of ISOBUS is: communication through a common language, independent from device and manufacturer. This has become especially important since many different manufacturers started developing electronic hardware and software applications to avoid functionality issues. Knowing that machinery on a farm might consist of equipment from different manufacturers, ISOBUS ensures standardised communication interfaces. Thanks to its reliable and secure operations, the number of machines equipped with ISOBUS is significantly increasing. The benefits of using ISOBUS technology and its wide range of functions are obvious. Our tractors can be equipped with ISOBUS, which allows to use a wide number of features. They include TECU, which works as a kind of “job computer” on the tractor. In addition, a rear (and optionally front) socket is available to connect an ISOBUS certified device from any manufacturer. Inside the cab, a terminal socket on the b-pillar allows to connect any ISOBUS compliant terminal. To operate an ISOBUS device, you can equip our machines with the iMonitor3, which is fully ISOBUS compliant. It is available in two sizes and provides various features – and many of them don't even need to be activated.

The iMonitor3 is our machines' core element for the performance of several important functions.